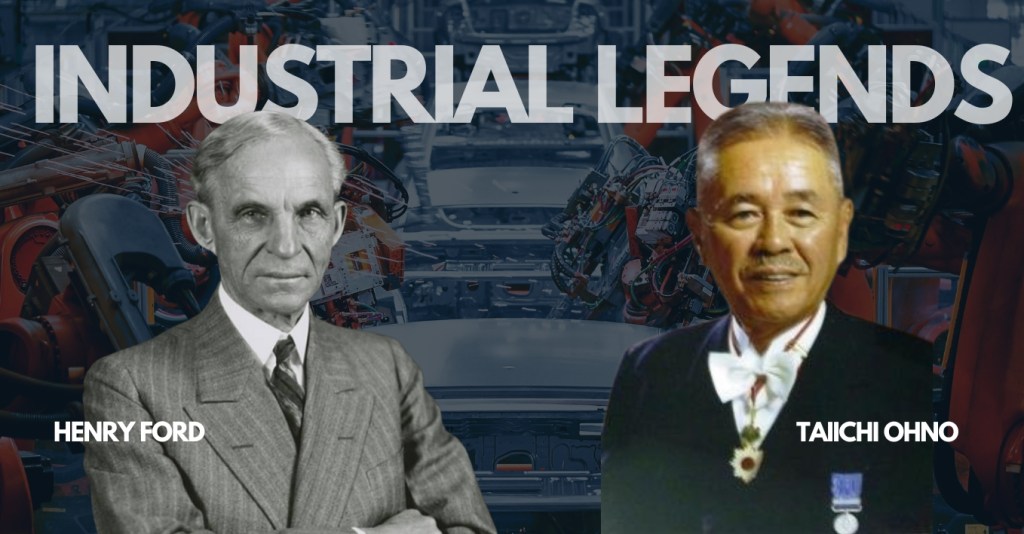

If Two Industrial Legends Walked Into Your Factory Today?

Imagine stepping into a grand auditorium filled with industrial executives, plant managers, and manufacturing engineers—all searching for answers to the mounting challenges of modern production. The anticipation is palpable. The stage is set. Suddenly, two of the most influential minds in industrial history take the stage: Henry Ford, the father of mass production, and Taiichi Ohno, the mastermind behind Lean Manufacturing.

If these two giants could speak directly to today’s leaders, what advice would they give? What lessons from the past would they use to illuminate the path forward?

Henry Ford’s Revolution: Mass Production and the Power of Standardization

Henry Ford was more than just an automotive mogul—he was a revolutionary thinker. Before his innovations, cars were luxury items, painstakingly assembled in small workshops. Ford envisioned a different future: cars affordable for every American.

His greatest contribution? The moving assembly line, an innovation that reduced the production time of the Model T from twelve hours to just ninety-three minutes. By implementing standardized parts, interchangeable components, and a highly synchronized workflow, Ford made mass production a reality, forever changing the face of manufacturing.

But his philosophy extended beyond efficiency. He made a bold decision to pay workers a $5 daily wage, doubling industry standards at the time. His reasoning was simple: a productive workforce and a prosperous middle class meant more customers for his cars.

Ford’s Core Principles:

✔ Efficiency through standardization – Eliminate unnecessary complexity; every part and process should be optimized for speed and consistency.

✔ Automation before it was popular – Machines should perform the repetitive work, allowing humans to focus on innovation.

✔ A well-paid workforce is a productive workforce – Investing in people fuels long-term growth.

📢 What would Ford say to today’s manufacturing leaders? 🚀 “If you cannot produce efficiently, you will not compete. Stop overcomplicating—simplify, standardize, and scale.”

Taiichi Ohno’s Philosophy: The Power of Continuous Improvement

If Henry Ford invented mass production, Taiichi Ohno perfected it. As the architect of the Toyota Production System (TPS), he refined manufacturing with a core philosophy: eliminate waste.

Unlike Ford’s rigid standardization, Ohno prioritized flexibility, adaptability, and relentless improvement. His system introduced concepts that are now global industry standards:

✔ Just-in-Time (JIT) – Produce only what is needed, when it is needed—no excess inventory, no wasted effort.

✔ Kaizen (Continuous Improvement) – Every day, every worker must look for ways to improve processes.

✔ Respect for People – Workers are problem-solvers, not just operators; empowering them leads to better decision-making and efficiency.

📢 What would Ohno tell today’s leaders? 🔥 “Your factories are filled with waste—you just don’t see it. Train your people to think Lean, eliminate inefficiencies, and let the data guide you.”

What Advice Would They Give Today’s Leaders?

If we could sit Ford and Ohno down for a private mentorship session, here’s what they would likely say:

1. “Standardize What You Can, Optimize What You Must”

Ford would advocate for standardization, as it reduces costs, improves efficiency, and ensures predictability. Ohno, however, would warn that rigid standardization without optimization creates hidden inefficiencies. The key is to balance consistency with adaptability.

📌 Lesson: If your processes are unstable, fix them before automating. Automation should not replace bad processes—it should enhance well-optimized processes.

2. “Your Problems Are in the Waste—Find It and Eliminate It”

Ohno dedicated his career to eliminating waste, and Ford would likely agree, pushing for automation and technology to streamline processes.

📌 Lesson: If your factory has long lead times, high inventory, or frequent defects, your problem isn’t competition—it’s waste within your own operation.

3. “Empower Your Workforce to Think and Innovate”

Ford believed that fair wages ensured a stable workforce. Ohno took it further, seeing frontline workers as the greatest asset for continuous improvement.

📌 Lesson: If your employees only follow instructions, your factory will never evolve. Train them to identify inefficiencies, suggest improvements, and take ownership of quality.

4. “Data is the New Fuel—Use It”

Ford pioneered industrial data collection, while Ohno implemented visual management and real-time tracking.

📌 Lesson: If you’re still making decisions based on monthly reports, instead of real-time data, you’re already behind.

5. “Don’t Just Follow Trends—Master Fundamentals First”

Many executives rush to adopt automation, AI, and digital transformation without first fixing their operational inefficiencies.

📌 Lesson: A smart factory built on inefficient foundations will only scale problems faster. Master Lean before adding Industry 4.0.

Final Thoughts: The Path Forward

If Henry Ford and Taiichi Ohno visited modern factories today, they would see a mix of brilliance and chaos. They would see companies using AI and robotics to optimize world-class production lines—but also factories drowning in inefficiency, mistaking automation for innovation.

🔥 Ford: “Stop overcomplicating—get back to basics, standardize, and scale.”

🔥 Ohno: “Your biggest problem is waste—eliminate it before doing anything else.”

As an industrial leader today, you have more tools, technology, and data than they ever dreamed of. But the real question is: 📌 Are you using these tools effectively, or just following trends?

📌 Are you leading transformation, or waiting for someone else to do it?

🚀 At Attitude Feelings, we help industrial leaders master Lean, optimize operations, and execute transformation with precision. If you’re ready to lead like Ford and think like Ohno, visit AttitudeFeelings.com.

By Anderson Waldrich Nunes | Attitude Feelings Co.