The Evolution of Industry and the Urgent Need for a Transformation Roadmap

The industrial world is in constant evolution. From the first steam-powered machines to today’s AI-driven factories, technological revolutions have reshaped the way we produce, compete, and innovate. Yet, despite all this progress, a harsh reality persists: many factories today do not even know where they stand in this journey.

Executives talk about digital transformation and Industry 4.0. Companies invest in automation, IoT, and machine learning. But when you step onto the shop floor, you often see a different story. Many factories that claim to be “modern” are, in reality, barely operating at Industry 2.0 standards—struggling with outdated processes, manual reporting, and inefficiencies that should have been eliminated decades ago.

It’s like trying to install AI in a factory that still tracks production on clipboards—a complete mismatch between ambition and reality.

If leaders don’t recognize where their factories actually stand in this evolutionary process, any attempt to move forward will be built on a foundation of inefficiency and poor execution. This article will break down the four key phases of industrial evolution, expose the critical gaps in American manufacturing, and lay out a roadmap for transformation—because knowing where you are is the first step to knowing where to go.

The Four Industrial Revolutions—Where Are You Really?

Before talking about where you want to go, you must understand where you are. The industrial world has undergone four major revolutions, each defined by groundbreaking advancements in technology, production efficiency, and decision-making processes.

Some industries are pioneers in adopting the latest innovations. Others, despite their ambition, remain trapped in outdated methodologies. The reality is that many American manufacturers believe they are operating at Industry 4.0 levels when, in fact, they are struggling to fully implement Industry 3.0—or worse, still functioning in an Industry 2.0 mindset.

The first step toward transformation is brutal honesty: where does your factory truly stand?

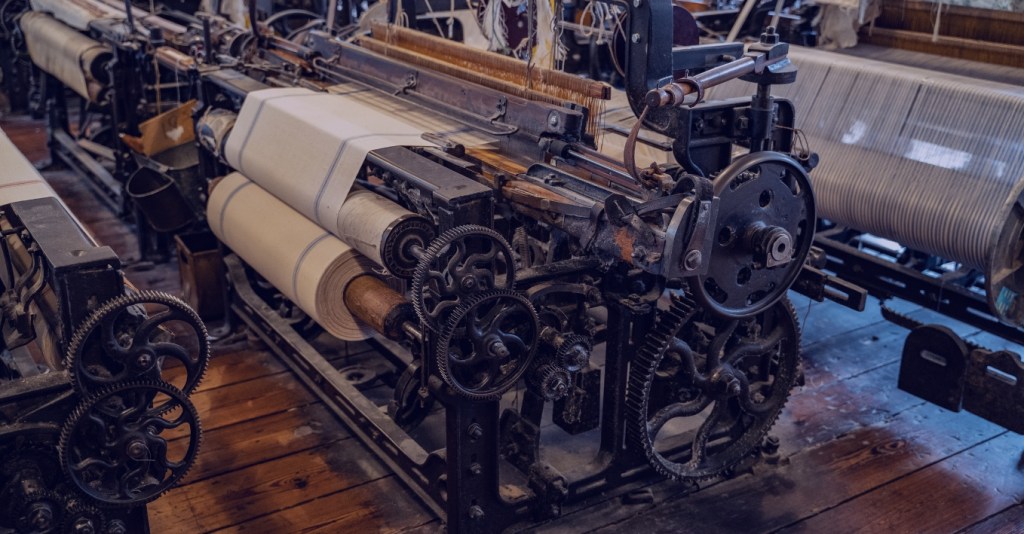

Industry 1.0 – The Birth of Mechanization (Late 1700s – 19th Century)

The First Industrial Revolution was a turning point in human history, marking the transition from handcrafted goods to mechanized production. Prior to this era, manufacturing was an artisanal process, dominated by skilled craftsmen who meticulously created products by hand in small workshops. Production was slow, inconsistent, and highly dependent on the expertise of individual workers.

Then came the steam engine, a groundbreaking invention that redefined the concept of manufacturing. The ability to harness steam power meant that factories were no longer restricted by human strength or animal labor. Instead, machines took over as the primary source of power, enabling mass production at an unprecedented scale.

However, while Industry 1.0 introduced the concept of large-scale manufacturing, it was far from efficient. Early factories were crude and chaotic, driven by sheer mechanical force rather than intelligence or precision. The absence of standardized production methods meant that quality was inconsistent, waste levels were high, and productivity was often hindered by frequent breakdowns and inefficiencies.

Despite these limitations, Industry 1.0 laid the foundation for industrialization by shifting manufacturing away from localized, small-scale craftsmanship toward centralized, factory-based production. This transition fueled economic growth, urbanization, and technological progress, setting the stage for future revolutions in industry.

Key Characteristics of Industry 1.0

✔ Steam-Powered Machinery – Replacing manual labor, allowing for increased production capacity.

✔ Factory System Emergence – Centralized production in large manufacturing plants instead of small workshops.

✔ No Standardization – Inconsistent quality, as production methods varied widely between factories.

✔ High Waste and Low Efficiency – Processes were driven by mechanical force without optimization.

✔ Skilled Labor Still Crucial – Despite mechanization, human expertise remained essential for troubleshooting and final assembly.

🚨 The Reality Today: Some Factories Still Operate in Industry 1.0 Mode

It might sound surprising, but many factories today still function with principles reminiscent of Industry 1.0—relying heavily on manual labor, outdated equipment, and lack of real-time data to make decisions. Without automation, digital connectivity, or standardized workflows, these operations remain stuck in the past, unable to compete with modern, lean-driven, data-powered manufacturing environments.

🔹 Is your factory still dependent on manual labor instead of automation?

🔹 Do you lack real-time data to monitor efficiency and quality?

🔹 Are your production processes still based on outdated trial-and-error methods?

If so, your factory is operating in an obsolete industrial model—and falling further behind competitors who have already evolved beyond these early inefficiencies. The need for modernization, process standardization, and automation has never been more critical. 🚀

Industry 2.0 – The Rise of Mass Production and Standardization (Late 19th Century – Mid 20th Century)

The Second Industrial Revolution marked a radical transformation in how goods were manufactured. With the introduction of electricity, factories were no longer reliant on the limitations of steam power. This shift increased efficiency, improved safety, and enabled factories to operate around the clock with a more stable and controllable energy source.

However, the real game-changer of Industry 2.0 was mass production and process standardization. The most iconic breakthrough of this era came from Henry Ford, who introduced the assembly line, redefining manufacturing forever. By breaking down production into specialized, repeatable tasks, Ford’s system drastically reduced production time and costs, making products—especially automobiles—more accessible to the general population.

Before mass production, manufacturing relied heavily on skilled craftsmanship, meaning each product was built individually, often leading to inconsistencies and inefficiencies. Ford’s revolutionary approach eliminated variability, increased scalability, and maximized efficiency, allowing businesses to grow at an unprecedented rate.

Despite these advancements, decision-making in Industry 2.0 was still slow. Manufacturing leaders relied heavily on intuition and past experiences rather than real-time data and analytics. While production speeds increased, quality control was still rudimentary, and issues like material waste, defective products, and inefficient labor allocation remained persistent challenges.

Key Characteristics of Industry 2.0

✔ Introduction of the Assembly Line – Increased speed, reduced costs, and mass standardization.

✔ Electrification of Factories – More reliable power sources allowed for continuous production.

✔ High Scalability but Limited Real-Time Process Control – Companies could produce in larger volumes, but data-driven decision-making was not yet a reality.

✔ Efficiency Based on Standard Work Procedures – Processes were structured but lacked flexibility and responsiveness to real-time production challenges.

✔ Quality Challenges Due to Limited Measurement Techniques – Inspection methods were basic, and defective products often reached customers.

🚨 The Reality Today: Are You Still Stuck in Industry 2.0?

Many companies that believe they are modernized are, in reality, still operating with Industry 2.0 principles. If your plant:

🔹 Relies on manual work orders instead of automated workflows,

🔹 Uses spreadsheets and static reports instead of real-time dashboards,

🔹 Depends on human intuition for problem-solving rather than data analytics,

🔹 Lacks predictive maintenance and relies on reactive problem-solving,

…then you are not as advanced as you think.

Factories that fail to move beyond Industry 2.0 struggle to compete with modern, data-driven manufacturing ecosystems. While assembly lines and standardized work remain critical, true industrial competitiveness today demands digital integration, automation, and real-time decision-making—principles that define Industry 4.0.

The question is: Are you optimizing your production like it’s 2024, or are you still operating like it’s 1924? 🚀

Industry 3.0 – The Digital and Automation Revolution (1970s – 2000s)

The Third Industrial Revolution introduced one of the most fundamental shifts in manufacturing history: the integration of computers, digital automation, and robotics. Before this era, factories were driven by manual labor and mechanical systems with limited intelligence and adaptability. The introduction of programmable logic controllers (PLCs) and computer numerical control (CNC) machines allowed industries to automate repetitive tasks, increasing precision and productivity while reducing dependency on human labor.

With digital computing now part of the manufacturing floor, data-driven production began to take shape. Companies could monitor performance, analyze trends, and refine processes based on historical data. Robotics became a staple in high-volume industries, particularly in automotive and electronics manufacturing, leading to consistent quality, higher speeds, and lower defect rates.

However, despite these advancements, Industry 3.0 still had limitations. The main challenge was that data was static, fragmented, and often disconnected from real-time operations. Manufacturers could track key metrics, but insights were typically gathered after production cycles had ended. Problem-solving remained reactive rather than proactive, meaning inefficiencies and equipment failures were only addressed after they had already caused disruptions.

Many companies mistakenly believed that automation alone was enough to secure efficiency, but without real-time monitoring, predictive analytics, and integrated systems, even highly automated factories still suffered from delays, waste, and unexpected breakdowns.

Key Characteristics of Industry 3.0

✔ Introduction of Digital Computers and PLCs – Enabled automated control of machines, improving efficiency and reducing reliance on manual operators.

✔ Rise of Robotics in Manufacturing – Robots began performing repetitive tasks with precision, boosting productivity and quality.

✔ Early Data Utilization – Companies started collecting performance data, but analysis was slow and lacked real-time visibility.

✔ Quality Control Improvements – Statistical process control (SPC) became more common, leading to better defect detection and waste reduction.

✔ Still Lacking Real-Time Process Adjustments – Factories relied on post-production data reviews rather than dynamic, instant process optimization.

🚨 The Reality Today: Is Your Factory Still Stuck in Industry 3.0?

Many manufacturers believe they are modernized simply because they use automation and digital tools, but automation alone does not equal progress. A McKinsey study found that 70% of companies still rely on outdated processes and manual workflows, preventing them from unlocking the full potential of digital transformation.

If your factory still:

🔹 Depends on Excel spreadsheets for tracking production,

🔹 Uses manual maintenance schedules instead of predictive analytics,

🔹 Relies on human inspections for quality control instead of AI-powered defect detection,

🔹 Has automated machines that operate in silos without connectivity,

…then you are stuck in the past and missing out on the true benefits of Industry 4.0.

The Next Step: From Digital to Intelligent Manufacturing

While Industry 3.0 brought automation, it lacked the intelligence and adaptability needed to predict, prevent, and optimize operations in real time. The modern manufacturing landscape demands connected systems, data-driven decision-making, and smart factories that self-adjust—this is the essence of Industry 4.0.

The companies that fail to move beyond Industry 3.0 will find themselves overtaken by competitors who embrace real-time analytics, IoT connectivity, and AI-driven optimization.

📌 Are you still running your factory like it’s the 1990s? Or are you prepared for the future of smart manufacturing? 🚀

Industry 4.0 – The Smart Factory Era (Today and Beyond)

The fourth industrial revolution is no longer a distant vision—it is unfolding in real-time. Industry 4.0 represents the convergence of physical and digital systems, where factories, supply chains, and entire manufacturing ecosystems become interconnected, intelligent, and autonomous. It is a radical shift that moves beyond simple automation and efficiency improvements. Instead, it aims to create self-learning, self-optimizing production systems that can adapt dynamically to changes in real-time.

At the core of Industry 4.0 is connectivity—a manufacturing environment where machines, systems, and people communicate seamlessly through the Internet of Things (IoT). This connectivity allows for real-time monitoring, predictive analytics, and AI-driven decision-making that reduces downtime, minimizes waste, and enhances productivity.

However, Industry 4.0 is more than just IoT sensors and automation. It is a data-driven revolution, where big data, machine learning, and artificial intelligence transform decision-making from reactive to predictive. Factories no longer wait for breakdowns to happen; instead, AI algorithms analyze historical data, anticipate failures, and initiate maintenance before disruptions occur. This predictive capability eliminates costly downtime, optimizes resource allocation, and ensures that production lines operate at peak efficiency.

Moreover, cyber-physical systems (CPS)—the integration of digital twins, robotics, and AI—allow manufacturing environments to adjust dynamically. Unlike previous industrial revolutions, where process improvements relied on human intervention, modern smart factories use adaptive automation, meaning machines learn from performance data and autonomously adjust operations to improve efficiency.

Key Characteristics of Industry 4.0

✔ IoT-Enabled Connectivity – Machines, sensors, and devices communicate in real time, creating a fully integrated production ecosystem.

✔ Real-Time Data Analytics – Manufacturing decisions are based on instant data insights rather than historical reports, enabling agile adjustments.

✔ AI-Driven Automation – Artificial intelligence identifies inefficiencies, predicts failures, and optimizes production schedules.

✔ Cyber-Physical Systems (CPS) – Digital twins simulate real-world production scenarios, allowing for process improvements before real-world implementation.

✔ Predictive Maintenance – Machine learning algorithms anticipate equipment failures, reducing downtime and increasing asset longevity.

✔ Decentralized Decision-Making – AI-powered systems allow real-time decision-making at the machine level, reducing reliance on centralized control structures.

🚨 The Reality Today: Compete or Fall Behind

Industry 4.0 is no longer a futuristic concept—it is already reshaping global manufacturing. Companies leveraging AI-powered supply chains, real-time IoT data, and autonomous production systems are achieving unparalleled efficiency, cost reductions, and competitive advantages.

If your factory still operates with manual data collection, outdated legacy systems, or reactive maintenance strategies, you are already falling behind. The question is no longer if you should adopt Industry 4.0, but how fast you can integrate these technologies before competitors take the lead.

🔹 Is your factory truly ready for Industry 4.0, or are you stuck in an outdated industrial model?

🔹 Are you leading the transformation or waiting for disruption to force you into action?

The future belongs to those who embrace change, adapt rapidly, and execute decisively. The time to act is now. 🚀

The Path to Transformation: Diagnose, Optimize, and Execute

Understanding where your factory stands in the industrial evolution is only the beginning. The real challenge lies in charting a clear path forward and executing the transformation effectively. The transition to Industry 4.0 is not simply about installing new technology or adding automation—it requires a fundamental shift in how companies think, operate, and make decisions.

The first and most critical step in this journey is eliminating inefficiencies before scaling operations with digital tools. Many companies mistakenly believe that digitalization will solve their problems when, in reality, technology only amplifies existing inefficiencies. If your production floor is plagued with waste, delays, and inconsistencies, automating those processes will not make them better—it will only make bad processes faster and more expensive.

To truly transform, companies must prioritize operational excellence first, then layer technology on top of a strong foundation. Lean Manufacturing principles must be embedded into the DNA of the organization. The relentless pursuit of waste elimination, improved workflows, and optimized production cycles must become the standard before any serious investment in automation or data-driven technologies can take place.

Once a company has optimized its processes, the next step is embracing real-time data as the core of decision-making. Gone are the days when production reports were printed at the end of the day, only for managers to react after the damage was already done. In the world of Industry 4.0, decisions need to be instantaneous, dynamic, and predictive. The use of IoT sensors, machine learning, and real-time dashboards is no longer optional—it’s the backbone of a competitive operation. Without a data-driven culture, even the most sophisticated technology will be useless.

Automation should come next—but it must be done with precision and strategic intent. The goal is not to simply replace human workers with robots but to augment human capabilities and create a seamless collaboration between man and machine. Automation should enhance efficiency, not add complexity. Factories that automate without first refining their processes will only scale inefficiency at an accelerated pace.

The future of manufacturing is not about reacting to problems after they arise—it’s about predicting and preventing them before they occur. This is where AI-driven predictive maintenance and machine learning algorithms play a crucial role. By identifying patterns and anomalies before they lead to system failures, companies can eliminate unplanned downtime, reduce maintenance costs, and maximize asset performance. Leaders who continue to rely on reactive strategies will find themselves outpaced by competitors who leverage predictive intelligence.

But no transformation will be successful without investing in people. A factory filled with advanced technology is useless if the workforce does not have the skills, mindset, and adaptability to operate within this new reality. Training employees to embrace digital tools, understand real-time analytics, and develop a continuous improvement mindset is just as important as implementing the technology itself. The transformation to Industry 4.0 is not just a technological shift—it is a cultural shift, and organizations that fail to prepare their workforce will struggle to sustain long-term success.

Final Thoughts: Compete or Disappear

American manufacturing is at a defining moment. The companies that will thrive in the coming decades are those that embrace data-driven decision-making, automation, and AI-powered efficiency. Those that cling to outdated processes, resist change, and hesitate to evolve will be left behind, watching as their competitors gain ground and dominate the market.

This is not a matter of choice anymore. Transformation is not optional—it’s survival. The industry has already changed, and the only question left to ask is:

📌 Are you driving the transformation, or are you being left behind?

📌 Is your factory truly ready for Industry 4.0, or are you still operating under illusions of modernization?

📌 Are you waiting for the perfect moment, or are you taking bold action today?

The time for hesitation is over. The manufacturing leaders who act decisively, leverage data intelligently, and execute relentlessly will shape the future. Those who wait for external change will wake up to find themselves irrelevant.

🚀 At Attitude Feelings, we help industrial leaders accelerate their transformation with Lean, IoT, and data-driven execution. The future belongs to those who take action. Are you ready to compete?

👉 Explore more insights at AttitudeFeelings.com.

By Anderson Waldrich Nunes | Attitude Feelings Co.